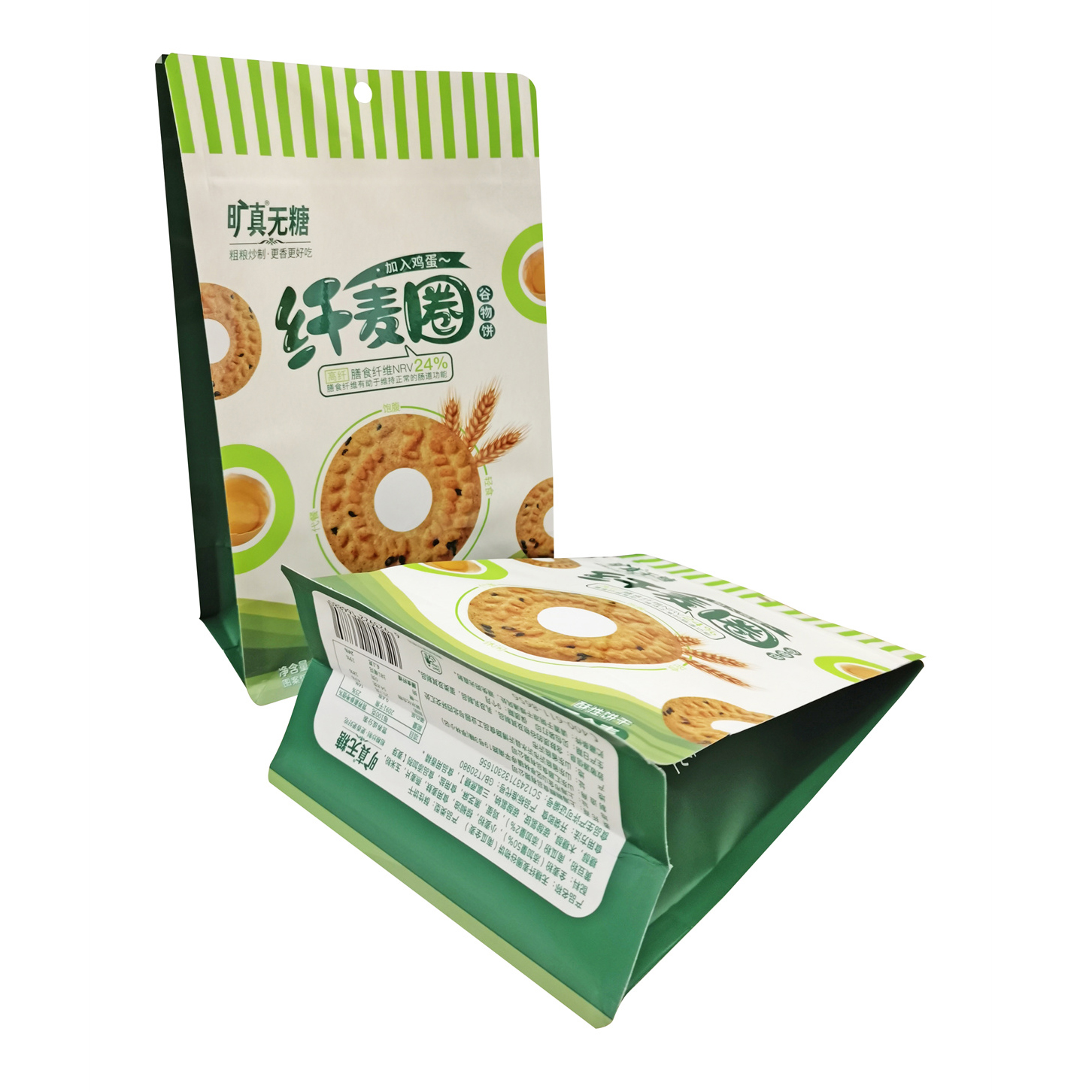

Shaped pouch changes the line edge into the curve edge, it can reflects the different design styles and has the features of originality, simple, clear, easy to identify and highlight the brand image. The appearance of shaped pouch has a very great significance to expand the packaging design form and make many more design dreams come true.

Compared with normal bag, shaped pouch has stronger appeal, clear product information and obvious promotion effect. It can add zipper, hang hole or spout to make the shape pouch more easy and humanized during the using process. If you decide to use shaped pouch, three points need pay more attention. Change normal pouch into shaped pouch, the size will have to be changed, the external rim can not with closed angle to avoid harm to other pouch or the user, the opening direction and seal position also require to be considered.

The printing of shaped pouch is same as other pouch, it can be normal printing or UV prining. The material can be chose for matt, glossy, foil inside, clear window according to the products feature. The bag size is no limitation, the client can test by real product to get the suitable one. If you are not sure for some information or bag details, just contact with Union Packing, we can help you solve the problems and turn your ideas into the real pouch.

| Product | Shaped pouch |

| Print ink | Normal ink or UV ink |

| Zipper | No zipper/regular zipper/tear zipper |

| Usage | Food packaging/industrial production |

| Size | No limit |

| Material | Matt/glossy/matt and glossy/foil inside |

| Thickness | Suggest 80 micron to 150 micron |

| Printing | Your own designs |

| MOQ | Based on the bag size for length and width |

| Production | About 10 to 15 days |

| Payment | 50% deposit, 50% balance before delivery |

| Delivery | Express/sea shipping/air shipping |

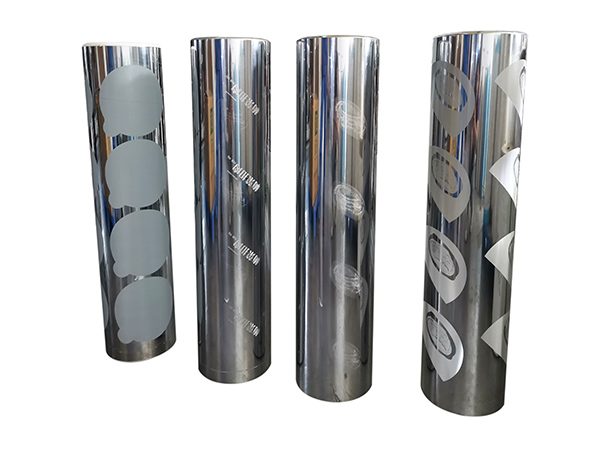

Material

Print plates

Printing

Laminating

Drying

Making-bag

Testing

Packing

Shipping

----We need know what detailed products will be packed, so give some advice on the material and thickness. If you have it, just let us know.

----Then, the bag size for length, width and bottom. If you don’t have it, we can send some sample bags to test and check quality together. After tested, just measure the size by ruler end to end.

----For printing design, show us to check print plate numbers if ok, normally AI or CDR or EPS or PSD or PDF vector graph format. We can provide blank template based on correct size if need.

----Bag details for tear mouth, hang hole, round corner or direct corner, regular or tear zipper, clear window or not, give correct quotation.

----For sample bags, we can send you free samples for all kinds of bag types to check the quality, feel the material and test with your products. So you can choose the one you really like. Just need the express charge.

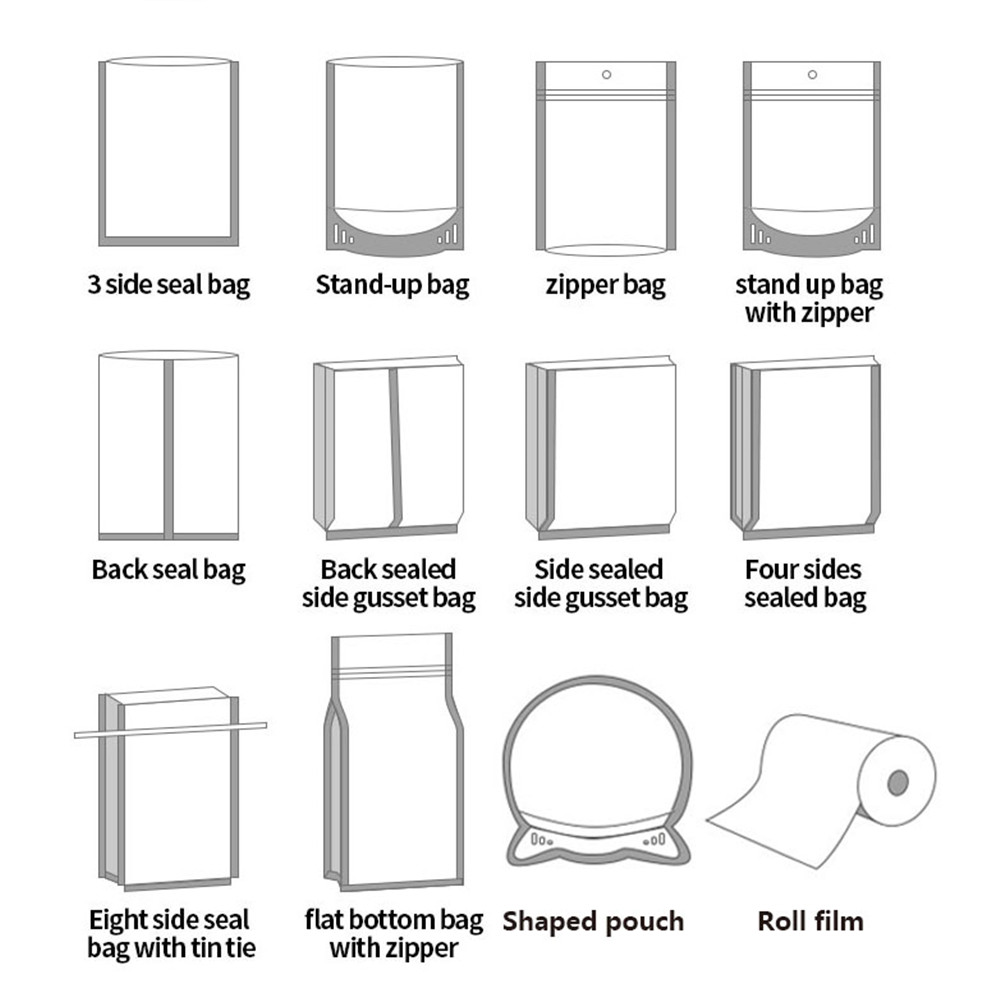

Choose The Bag Type

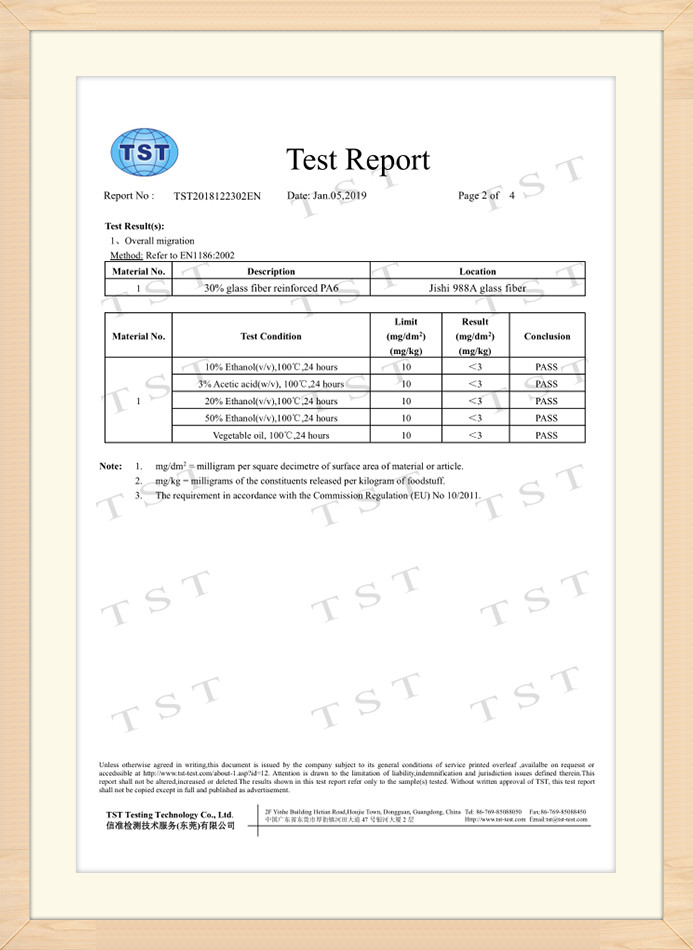

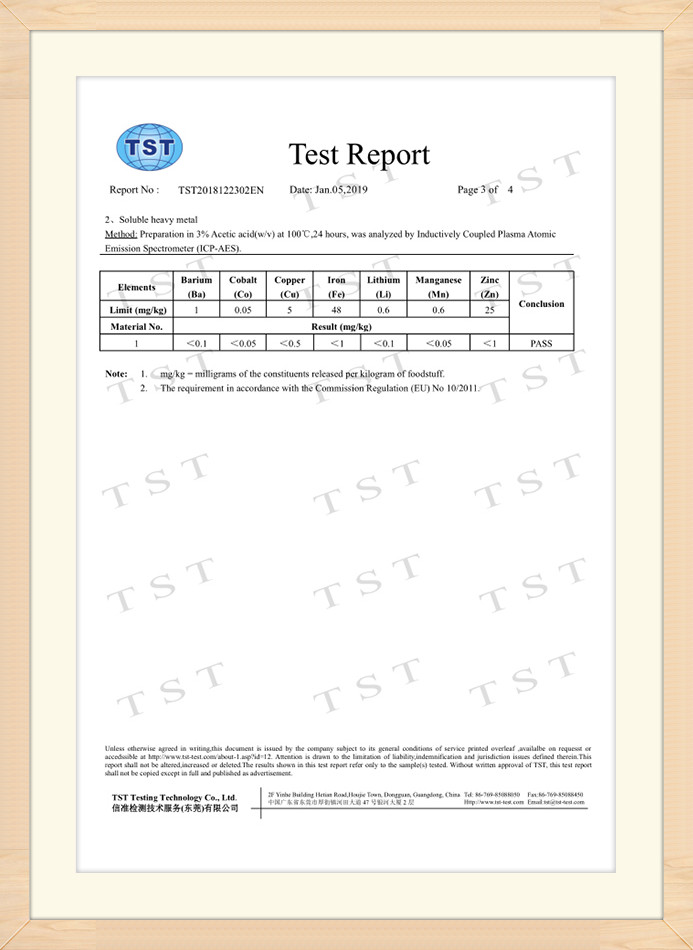

Certificate

Our Customers Comments