Retort pouch is light and easy to storage, compared with metal tins, it can save much space and save sterilization energy sources. The food in retort pouch no need frozen but it can have long time quality guarantee period. Because of the strength, flexibility and light weight, retort pouch have become a widely used alternative packaging to traditional cans pack, just 5% packaging material of traditional tin cans and help improve food quality and flavor.

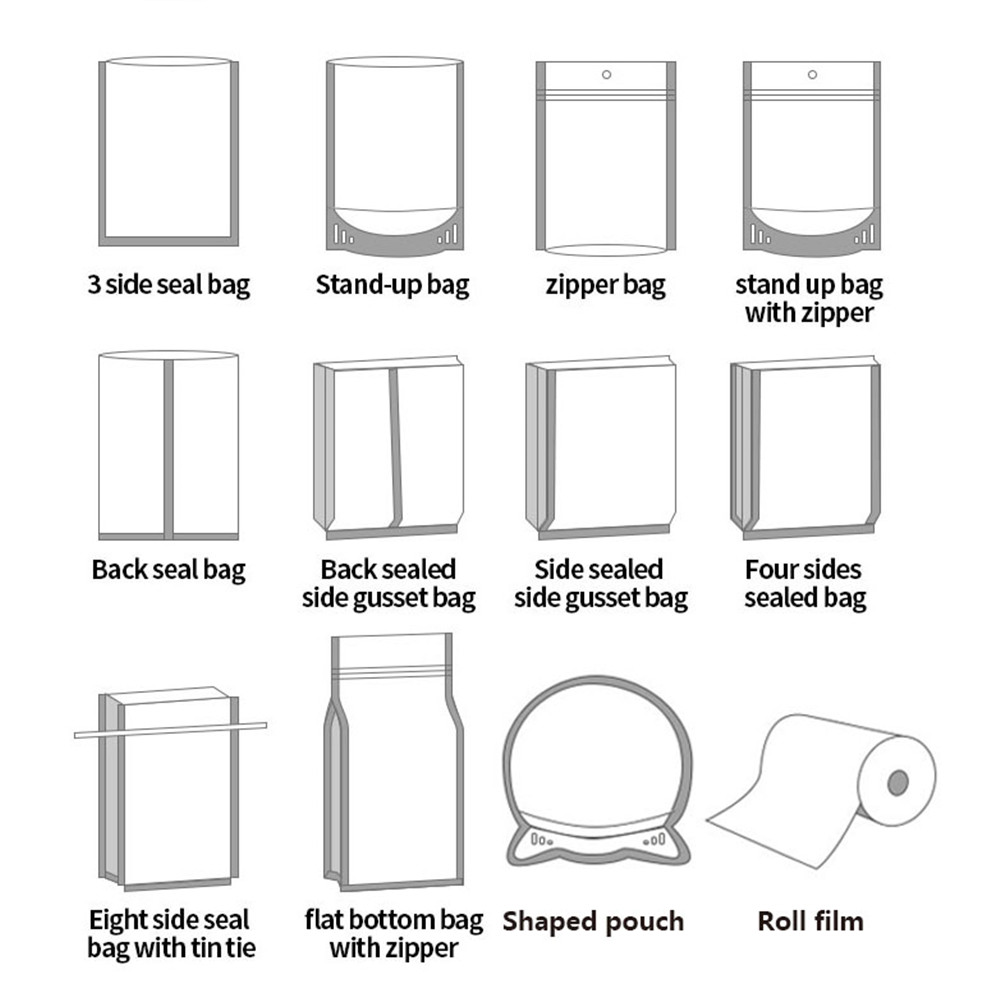

Some clients use three side seal bag type to retort, others prefer stand up pouch for its attractive surface and stand well. Retort pouch can be printed 100% customized, Union Packing will print your own designs on bags to look professional and choose the most suitable materials to fit the products be packed. Bag details for round corner, hang hole and tear mouth, we will obey our clients’ thoughts. Retort pouch can pack ready-to-eat meals with liquid or sauce, so it can meet different tastes of all consumers. That is to say, one product can be divided into several tastes for consumers to choose what they are like, designs are similar but in different color or words, Union Packing will help you do it well. Just tell Union Packing what you are looking for, what products will be packed, Union Packing will give the satisfied opinion. Believe in your choice, Union Packing will be the right place for all the packaging bags.

| Product | Retort pouch for high temperature sterilization |

| Print ink | Normal ink or UV ink |

| Zipper | No zipper |

| Usage | Food packaging/industrial production |

| Size | No limit |

| Material | Matt/glossy/matt and glossy/foil inside |

| Thickness | Suggest 80 micron to 140 micron |

| Printing | Your own designs |

| MOQ | Based on the bag size for length and width |

| Production | About 10 to 15 days |

| Payment | 50% deposit, 50% balance before delivery |

| Delivery | Express/sea shipping/air shipping |

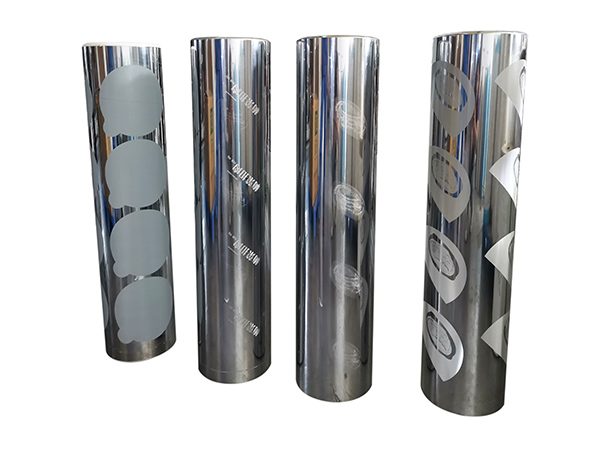

Material

Print plates

Printing

Laminating

Drying

Making-bag

Testing

Packing

Shipping

----We need know what detailed products will be packed, so give some advice on the material and thickness. If you have it, just let us know.

----Then, the bag size for length, width and bottom. If you don’t have it, we can send some sample bags to test and check quality together. After tested, just measure the size by ruler end to end.

----For printing design, show us to check print plate numbers if ok, normally AI or CDR or EPS or PSD or PDF vector graph format. We can provide blank template based on correct size if need.

----Bag details for tear mouth, hang hole, round corner or direct corner, regular or tear zipper, clear window or not, give correct quotation.

----For sample bags, we can send you free samples for all kinds of bag types to check the quality, feel the material and test with your products. So you can choose the one you really like. Just need the express charge.

Choose The Bag Type

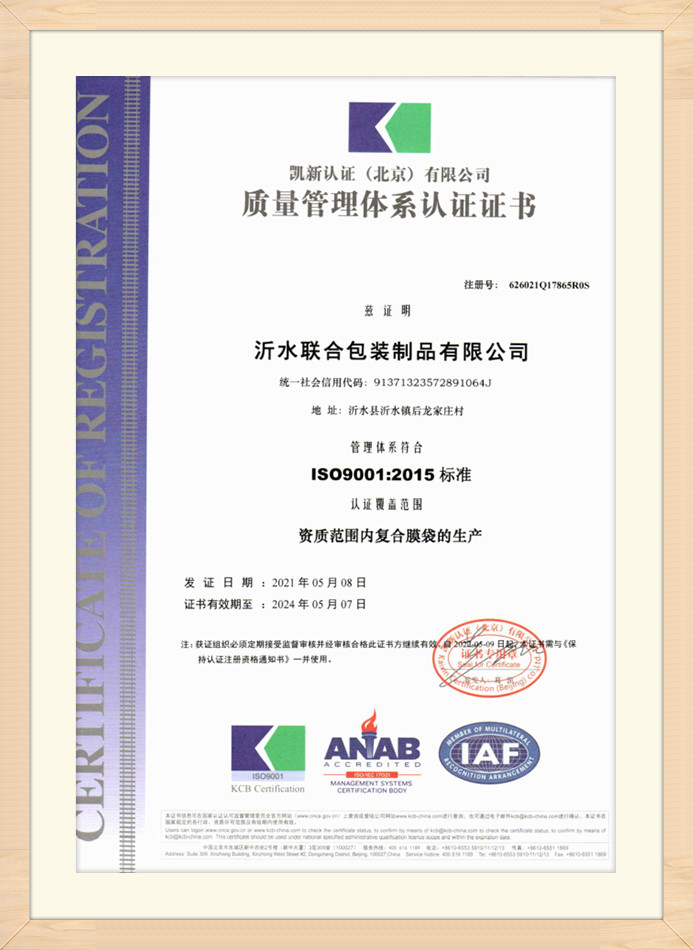

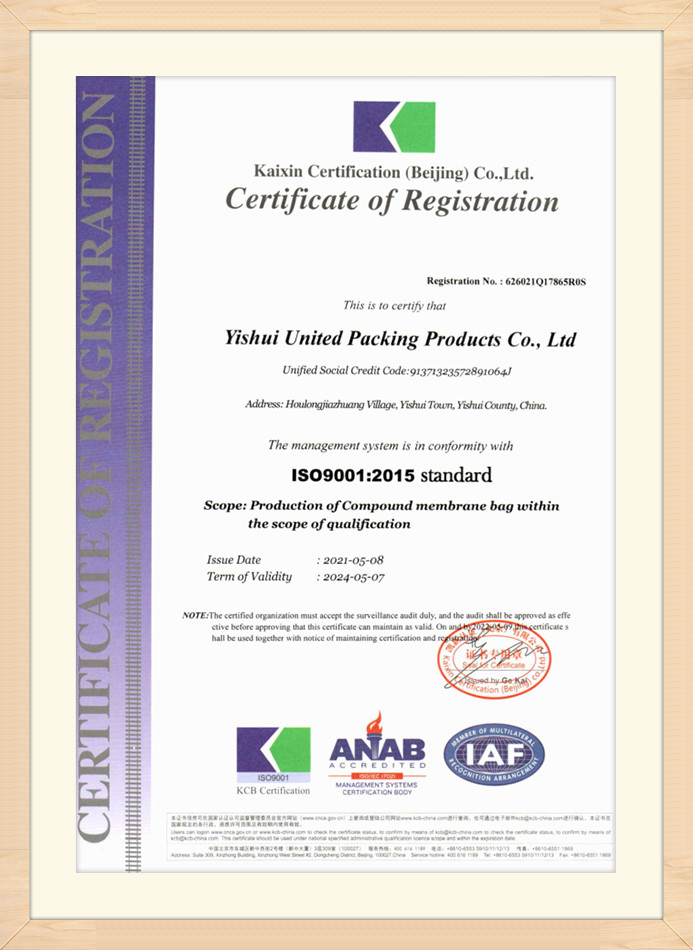

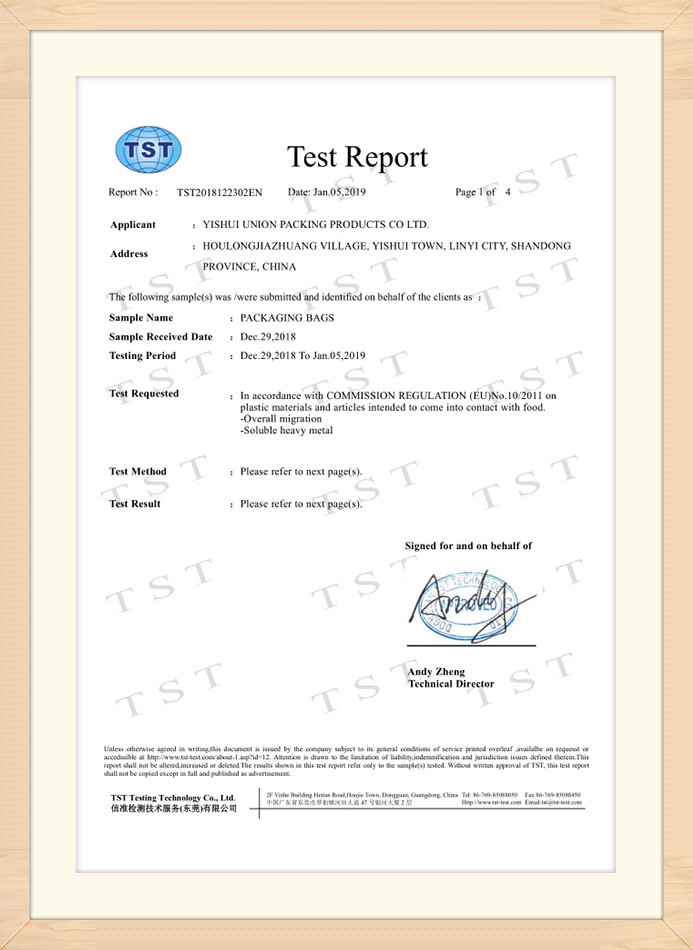

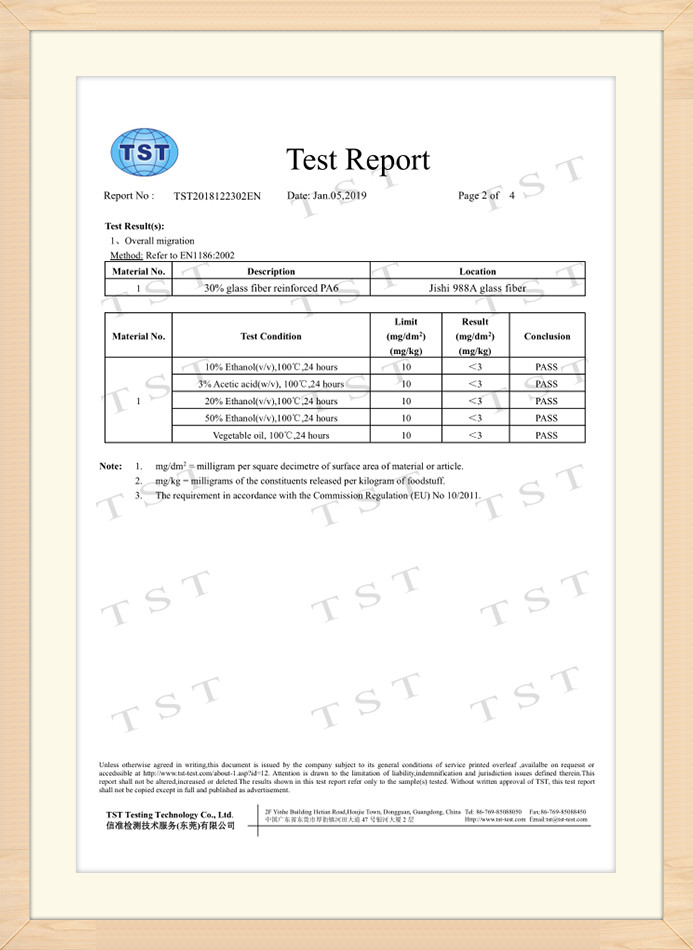

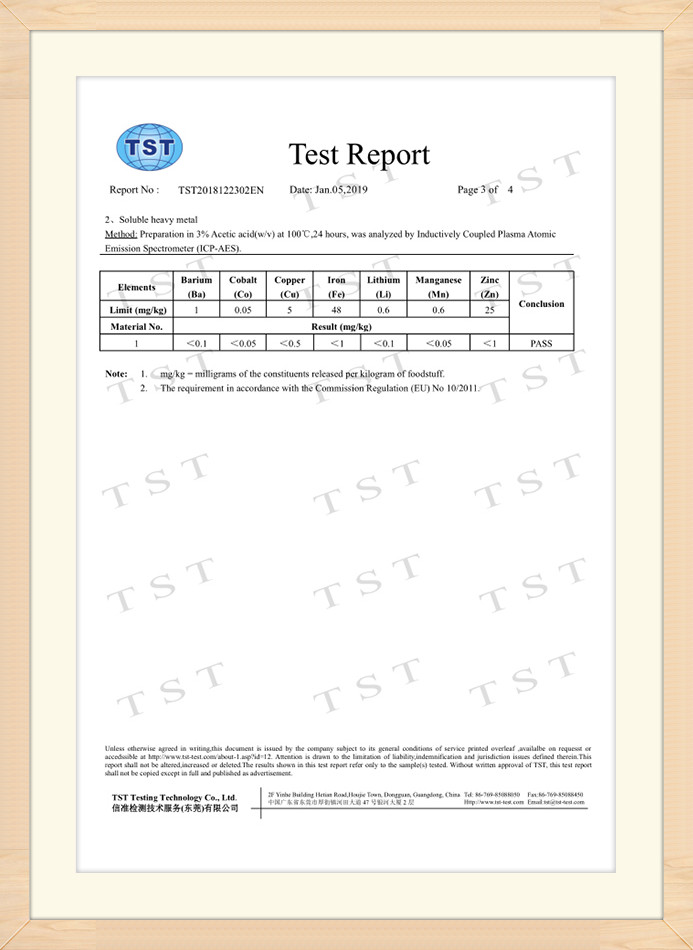

Certificate

Our Customers Comments